Axis-Inspect-Master 90°

Productgroup: 216-801 - 216-803

Inklusive rückführbarem Qualitätsprüfzertifikat - kostenlos -

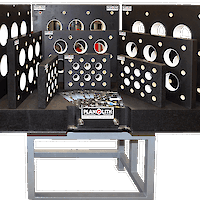

Axis-Inspect-Master 90°

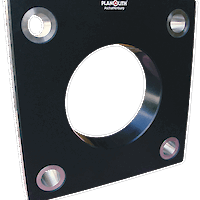

Rectangular, out of black natural hard stone, five-sided accuracy. For weight reduction and better handling machined with reduction bores. The four small outer flats are worked parallel and rectangular to each other. Equipped with twelve mating boreholes for faster and easier examination of positions.

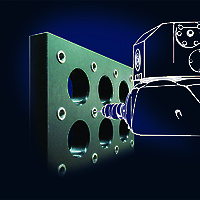

The Axis Inspect Master

is a measuring- and inspection tool for CNC-driven machine tools and measuring machines. It allows a fast and precise analysis of the actual condition of a certain machine. The determined datas have to be compared to given demand values to assert the actual condition. Depending on the given equipment of the machine, this can be done automatically.

It’s very important to check and recalibrate the positions of a machine after a crash in a very short time. This can save precious time and money by making it unnecessary to call a service specialist in small cases and reducing the downtime of the machine to a minimum.

Five sides and the mating boreholes on the Axis-Inspect-Master are engineered very accurately. The same applies to the corner of the narrow surfaces. For this reason the desired surfaces can be drawn for measuring.

This makes the Axis-Inspect-Master multifunctional and economical in a lot of industrial fields.

We also offer a suitable flight case for our precision measuring equipment.

| measurements approx. mm | weight approx. kg | perm. deviation of squareness in mm | flatness of small surfaces in mm | flatness of one large surface in mm | number of fits | order-no. |

|---|---|---|---|---|---|---|

| 350 x 250 x 50 | 15 | 0,002 | 0,002 | 0,01 | 12 | 216-801 |

| 600 x 400 x 50 | 32 | 0,002 | 0,002 | 0,01 | 12 | 216-802 |

| 800 x 600 x 70 | 90 | 0,002 | 0,002 | 0,01 | 12 | 216-803 |

You are interested in this product?

Send us a message and we will get back to you as soon as we possibly can.

Stefan Hein

Managing Director

For mechanical engineers

For mechanical engineers