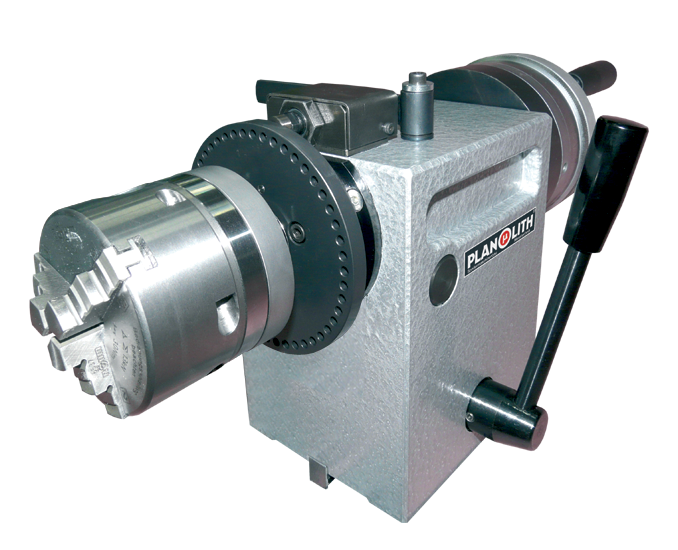

Headstock (special cast iron)

Productgroup: 245-202 - 249-205

Headstock (special cast iron)

In anespecially high wear resistance. The spindle which is supported to high precision is made of hardened steel, precision ground and adjusted. It has a concentricity of 0,004 mm. The centre sleeve is directly adjusted by a handwheel. An adjusting accuracy up to 3 arc minutes can be achieved. Index plate and nonius are matt chrome plated. The headstock is equipped with a clamp and release mechanism that works mechanically. It assures the firm connection of hand operated chucks, collets, centre, carrier plate, face plates and permanent magnet with the headstock. If desired, the device is equipped with a grating mechanism - smallest intervall 7,5° - or with a motor driven spindle (spindle revolution stepless adjustable).

No. 248-202 - 248-205

Manual chuck

self-centering with an adjusting accuracy of 0,01 mm.

No. 249-202 - 249-205

Counter tailstock

with handwheel adjustment and an accuracy of axis of 0,004 mm to headstock.

| height of axis approx. mm | inside taper MK | total length approx. mm | weight approx. kg | order-no. with rotary sleeve | order-no. with release mech. | order-no. motor driven spindle |

|---|---|---|---|---|---|---|

| 150 | 2 | 200 | 20 | 245-202 | 246-202 | 247-202 |

| 200 | 2 | 220 | 23 | 245-203 | 246-203 | 247-203 |

| 250 | 3 | 270 | 40 | 245-204 | 246-204 | 247-204 |

| 300 | 3 | 310 | 52 | 245-205 | 246-205 | 247-205 |

| Manual chuck with intermediate flange | Counter tailstock | ||||

|---|---|---|---|---|---|

| clamping reach ø mm | weight approx. kg | order-no. | height of axis approx. mm | weight approx. kg | order-no. |

| 80 | 2,9 | 248-202 | 150 | 15,0 | 249-202 |

| 100 | 6,8 | 248-203 | 200 | 17,0 | 249-203 |

| 160 | 14,8 | 248-204 | 250 | 40,0 | 249-204 |

| 200 | 24,6 | 248-205 | 300 | 48,0 | 249-205 |

You are interested in this product?

Send us a message and we will get back to you as soon as we possibly can.

Stefan Hein

Managing Director

For mechanical engineers

For mechanical engineers